Direct steam retort is the simplest and most dependable type of autoclave that provides a proven method for tin can sterilization. During the sterilization, the air is evacuated from the retort by flooding the vessel with steam, exhausting air through the vent valve. There is no overpressure during the sterilization phases, because air is not permitted to enter the vessel at any time during the sterilization step. But there may be air overpressure applied during the cooling steps to prevent container deformation.

In compliance with the requirements of FDA/USDA, the direct steam retort is optimized for automation and energy saving. Our steam retort has been widely used in canned food factories and is still favored by many customers.

(the above sizes can support 2 to 6 baskets)

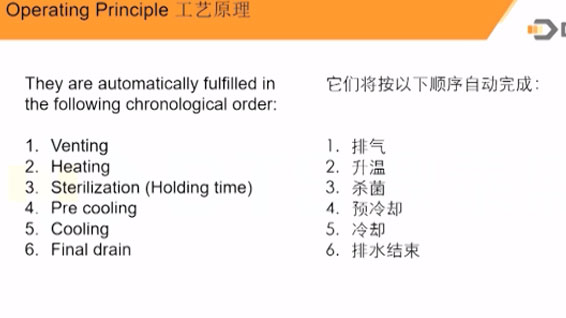

First, send product into the sterilization retort in a basket and then close the door, which is secured by a triple safety interlock. The whole sterilization process is then automated and controlled by PLC.

Next, steam is introduced into the chamber through a diffusion pipe inside the retort while air is expelled through an exhaust port. Once the pre-set time and temperature for exhaust are achieved, the heating phase commences. It’s crucial to maintain saturated steam in the chamber throughout the heating and sterilization process, without any residual air to prevent uneven heat distribution, leading to incomplete sterilization. The vent outlet remains open during the entire process, ensuring convection currents to maintain uniform temperature.

The cooling phase occurs in two stages, mild cooling and full cooling. The former helps to prevent pressure loss within the retort and ensures that product packaging remains intact without getting distorted.

Because saturated steam is used for sterilization, the pressure in the sterilization retort corresponds exactly to the saturation pressure of the steam and is only suitable for rigid containers with a wide range of pressure requirements, such as iron cans.

The temperature distribution inside the retort has a uniformity of +/- 0.5℃.

DTS is experienced and devoted to the manufacturing of consistent, high-quality sterilization equipment for packaged food and beverage.

DTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.