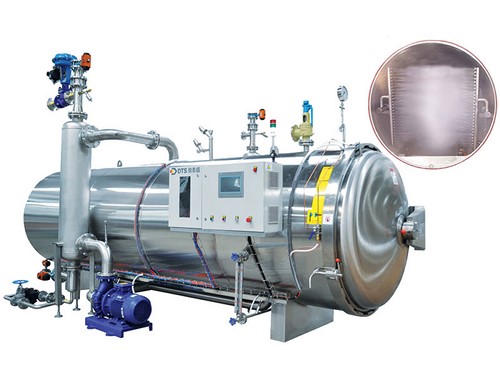

DTS offers 3 different types of water spray retort for your food sterilization needs, including water spray retort, cascading retort and sides spray retort. The water is pumped to spray evenly throughout the vessel and heats the product with excellent temperature distribution. With the micro-processing controller PLC, the sterilization process is automatically performed and the temperature and pressure inside the retort are accurately controlled following the recipe (with a temperature uniformity of ±0.5℃ and a pressure uniformity of ±0.05bar).

The pressure inside the retort is not influenced by the temperature, and it can be freely set according to the package of products. This allows the water spray retort for wider application, including 2-piece cans, 3-piece cans, flexible packages, glass bottles, plastic packages and other kinds of packages.

Water spray sterilization retort is equipped with a heat exchanger for heating and cooling, thus preventing products from being contaminated by steam and cooling water while also eliminating the need for water treatment chemicals. The process water is drawn by a water pump, and continuously sprayed onto every inch of products by the spray nozzles distributed throughout the retort for the sterilization goal. Accurate temperature and pressure control make this sterilization retort perfect for sterilizing food and beverages packaged in various containers.

Water Cascade Retort is equipped with a heat exchanger for heating and cooling, thus preventing products from being contaminated by steam and cooling water while also eliminating the need for water treatment chemicals. The process water flows from top to bottom in a uniform manner via the large-flow water pump and metal plate in the top of the retort. Accurate temperature and pressure control make this sterilization retort perfect for sterilizing food and beverages packaged in various containers.

Side spray retort is a great fit for flexible pouches, especially heat-sensitive products. A heat exchanger is applied for heating and cooling, which prevents products from being contaminated by steam and cooling water. This also eliminates the need for adding water treatment chemicals (like chlorine). The process water is drawn by a water pump, and sprayed evenly onto the products through the spray nozzles located at the four corners of each retort tray, thus achieving the goal of sterilization while ensuring temperature uniformity during the heating and cooling processes.

From the end of 2019 to 2021, after experiencing the global epidemic and other difficulties, the sterilization line customized by DTS for Malaysia’s Nestle coffee has been successfully delivered and put into use.

Read More

DTS’s good reputation is not just built on the sterilization systems we supply, but the support and service we offer. The profitability of your business relatively depends on the performance, reliability and availability of your equipment.

Read MoreDTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.