Side spray retort is a great fit for flexible pouches, especially heat-sensitive products. A heat exchanger is applied for heating and cooling, which prevents products from being contaminated by steam and cooling water. This also eliminates the need for adding water treatment chemicals (like chlorine). The process water is drawn by a water pump, and sprayed evenly onto the products through the spray nozzles located at the four corners of each retort tray, thus achieving the goal of sterilization while ensuring temperature uniformity during the heating and cooling processes.

| Model | Diameter (mm) | Cylinder Length (mm) | Volumn (m³) | Overall Length (mm) | Overall Width (mm) | Overall Height (mm) | Basket Size (L×W×H/mm) | Designed Temperature (℃) | Tested Pressure (Mpa) | Designed Pressure (Mpa) |

| |

1000 | 1600 | 1.49 | 3200 | 1850 | 2200 | 745×665×631 | 147/156 | 0.44/0.56 | 0.35/0.45 |

| 1000 | 2400 | 2.12 | 4000 | 1850 | 2200 | 745×665×631 | ||||

| 1200 | 2700 | 3.45 | 3800 | 2350 | 2400 | 860×800×775 | ||||

| 1200 | 3600 | 4.47 | 4400 | 2350 | 2400 | 860×800×775 | ||||

| 1200 | 4500 | 5.49 | 5300 | 2350 | 2500 | 860×800×775 | ||||

| 1400 | 3000 | 5.24 | 3900 | 2450 | 2700 | 920×920×915 | ||||

| 1400 | 3900 | 6.62 | 4800 | 2450 | 2700 | 920×920×915 | ||||

| 1500 | 4250 | 8.26 | 5200 | 2600 | 3250 | 1000×1000×975 | ||||

| 1500 | 5300 | 10.12 | 6300 | 2600 | 3250 | 1000×1000×975 | ||||

| 1600 | 5650 | 12.27 | 6700 | 2900 | 3300 | 1070×1070×1050 | ||||

| 1600 | 6800 | 14.58 | 7900 | 2900 | 3300 | 1070×1070×1050 | ||||

| 1800 | 6500 | 17.81 | 7400 | 3100 | 3500 | 1220×1220×1170 | ||||

| 1800 | 7800 | 21.12 | 8700 | 3100 | 3500 | 1220×1220×1170 |

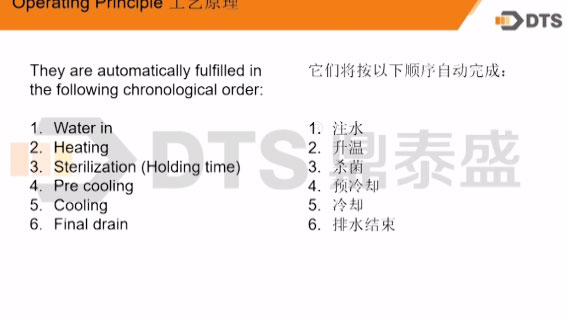

First, inject process water into the resort. The water can be pre-heated for sterilizing hot-filling products.

Next, switch on the high-flow pump and four-directional spray nozzles on each product tray. The result is that all products, regardless of their position in the tray, top or bottom layer, front or back, receive the same level of sterilization. This is achieved by ensuring that the heating and sterilization quality are ideal. The precise and accurate nozzle direction allows for even hot water diffusion at the center of each tray, which minimizes uneven temperature distribution within the large sterilizer’s processing tank.

The tubular heat exchanger in the retort allows the process water to flow in one side, and the steam in the other, so that germ-free sterilization can be achieved as the product won’t come directly into contact with the steam. The pressure inside the sterilization retort is set by program-controlled automatic valves that allow compressed air flowing into or out of the resort. Since the technique adopted is water spray, the pressure can be freely adjusted according to the package of sterilized product, and will not be affected by temperature. This would make the sterilization equipment more widely applicable in three-piece cans, two-piece cans, flexible packaging bags, glass bottles, plastic packaging, etc.

Finally, wait for the alarm signal for completing the sterilization. And the door can then be opened and the product can be unloaded, after which the equipment is ready to sterilize the next batch of products.

The temperature distribution inside the retort has a uniformity of +/- 0.5℃. The pressure is controlled at 0.05 bar.

DTS is experienced and devoted to the manufacturing of consistent, high-quality sterilization equipment for packaged food and beverage.

DTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.