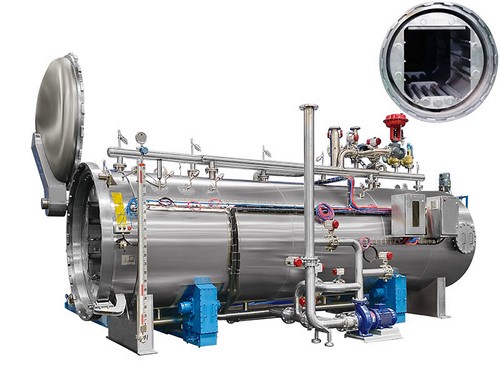

DTS rotary retorts are designed to efficiently sterilize a wide variety of products packaged in rigid, semi-rigid and flexible containers. It is ideally suited for handling products that benefit from agitation during the cooking and cooling phases to enhance overall product quality. The rotary agitation capabilities further enhance the flexibility of the machine by delivering fast and efficient processes for heat sensitive and/or other convective heating and cooling products. Our rotary retort is optional in three modes: water spray, water immersion and steam.

The rotating motion of water immersion rotary retort accelerates the heat transfer rates of the products inside the package and delivers uniform temperature distribution inside the retort. The retort provides reduced come-up times by introducing preheated water from the storage tank. Water conservation is improved by the recapture of process water following the sterilization process.

Water spray rotary retort utilizes the rotating motion to accelerate the heat transfer rates of the products inside the package. A heat exchanger is used for heating and cooling, thus preventing products from being contaminated by steam and cooling water. The process water is drawn by a water pump, and continuously sprayed onto every inch of products by the spray nozzles distributed throughout the retort for the sterilization goal.

Steam rotary retort uses the rotating motion to accelerate the heat transfer rates of the products inside the package. During the sterilization, the air is evacuated from the retort by flooding the vessel with steam, exhausting air through the vent valve. There is no overpressure during the sterilization phases, because air is not permitted to enter the vessel at any time during the sterilization step. But there may be air overpressure applied during the cooling steps to prevent the container deformation.

From the end of 2019 to 2021, after experiencing the global epidemic and other difficulties, the sterilization line customized by DTS for Malaysia’s Nestle coffee has been successfully delivered and put into use.

Read MoreDTS’s good reputation is not just built on the sterilization systems we supply, but the support and service we offer. The profitability of your business relatively depends on the performance, reliability and availability of your equipment.

Read MoreDTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.