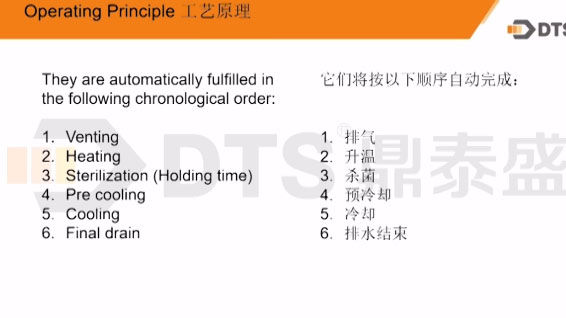

Steam-air retort is added with a fan as a driving force to mix the steam and air, and to prevent cold spots in the machine. The heating medium and the processed food packages are in direct contact and in forced convective heating. In addition, the air is allowed to be introduced into the vessel during the sterilization. Moreover, the temperature and pressure can be controlled independently. This retort conducts several stages, which can be properly set and executed according to the type of the food package.

| Model | Diameter (mm) | Cylinder Length (mm) | Volumn (m³) | Overall Length (mm) | Overall Width (mm) | Overall Height (mm) | Basket Size (L×W×H/mm) | Designed Temperature (℃) | Tested Pressure (Mpa) | Designed Pressure (Mpa) |

| |

1200 | 2400 | 3.1 | 4500 | 2350 | 2300 | 800×800×775 | 147 | 0.44 | 0.35 |

| |

1200 | 3600 | 4.5 | 5100 | 2350 | 2300 | 750×760×775 | |||

| |

1200 | 4500 | 5.5 | 6000 | 2350 | 2300 | 750×760×775 |

Just send the product into the sterilization retort in a basket and then close the door, which is secured by a triple safety interlock. The whole sterilization process is then automated and controlled by PLC.

This sterilization system utilizes steam to heat food packaging directly without the need for any other heating medium, such as water used as an intermediary through a spray system. Thanks to a powerful fan that creates circulation within the retort, the steam is evenly distributed. The fan also accelerates the transfer of heat between the steam and the food packaging, resulting in efficient heating.

The pressure inside the sterilization retort is set by program-controlled automatic valves that allow compressed air flowing into or out of the resort. Since the technique adopted is steam air sterilization, the pressure can be freely adjusted according to the package of sterilized product, and will not be affected by temperature. This would make the sterilization equipment more widely applicable in three-piece cans, two-piece cans, flexible packaging bags, glass bottles, plastic packaging, etc.

The temperature distribution inside the retort has a uniformity of +/- 0.3℃. The pressure is controlled at 0.05 bar.

DTS is experienced and devoted to the manufacturing of consistent, high-quality sterilization equipment for packaged food and beverage.

DTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.