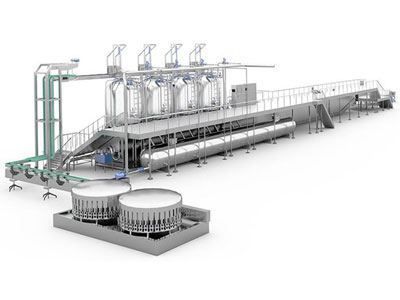

DTS is experienced and devoted to the manufacturing of consistent, high-quality sterilization equipment for packaged food and beverage. In addition to the batch retorts, we also provide customers with various kinds of continuous retorts, which offers advantages of constant product flow, high working efficiency and minimum operators. Continuous sterilizers at DTS include automated batch retort system (ABRS), vertical continuous sterilizing system, and continuous hydro static sterilizer, with the supporting automatic loading and unloading system.

The development trend of food processing is from small vessels to large sterilization retorts so as to improve efficiency and product safety and reduce energy consumption. Larger retort requires larger baskets which cannot be handled manually. The higher labor cost also promoted the gradual change from manual operation to automatic processing.

The vertical crateless retort system is a continuous sterilization line that overcomes a variety of technological bottlenecks in the sterilization industry. This sterilizing system features high technology, advanced technology, good sterilization effect, simple structure of the sterilized cans orientation system.

Automatic loader/unloader system is developed in response to the market needs of continuous loading and conveying of the products, aiming at providing stable and reliable operation, as well as high working efficiency. DTS specializes in the R&D, production and commissioning of loading and unloading system for retort sterilization. We can also make reasonable layout according to the different situations and needs of customers.

If your retort vents steam into the atmosphere, DTS steam autoclave energy recovery system will convert this energy into usable hot water without affecting the FDA/USDA heat treatment exhaust requirements. This sustainable solution can save a lot of energy and protect the environment by reducing factory emissions.

DTS retort thermal process monitoring system (option)

Retort host monitoring system (option)

F0 value system

Remote Service Support

From the end of 2019 to 2021, after experiencing the global epidemic and other difficulties, the sterilization line customized by DTS for Malaysia’s Nestle coffee has been successfully delivered and put into use.

Read More

DTS’s good reputation is not just built on the sterilization systems we supply, but the support and service we offer. The profitability of your business relatively depends on the performance, reliability and availability of your equipment.

Read MoreDTS is a professional supplier of sterilization equipment and nonstandard sterilizing lines for food and beverage products. We are specialized in the integration of raw material supply, product R&D, process design, manufacturing, finished product inspection, engineering transportation and after-sales service. Our sterilization retorts are available in batch, rotary and continuous modes, and can be applied to process products packaged in all kinds of containers, such as rigid containers, semi-rigid containers, flexible containers, Tetra Recart, etc.